From Product to Packaging: Our Full-Process Export Logistics Packaging Standards –For Welding Wires

When new clients cooperate with us for the first time, they always ask with a hint of anxiety: “How will my welding wires be packaged? Will corners be cut on materials? Will they get damp or oxidized during transportation?”

We fully understand this concern – take flux-cored welding wires as an example. As “precision consumables” for industrial production, even a trace of moisture or a slight bump during transportation can affect welding quality, ultimately delaying the client’s production schedule and harming their reputation. It is precisely because we understand this worry that we have refined a “from inside out” full-process export packaging standard tailored to the characteristics of flux-cored welding wires. Every step is dedicated to ensuring “safe arrival of goods”.

Step 1: Dress Welding Wires in “Vacuum Protective Covers” to Block All External Risks

What do flux-cored welding wires fear most? Moisture, oxidation, and rust. If the packaging is not sufficiently sealed, the wires are prone to rust when exposed to the high-humidity environment at sea during long-distance transportation – and in severe cases, this can even damage the stability of the weld metal composition after welding.

That’s why our first step is to individually wrap each spool of welding wire in a “vacuum aluminum foil protective cover”. It not only locks in the dry state of the welding wires tightly, isolating moisture and oxygen in the air, but also resists mild corrosion. Even if there are temperature fluctuations inside the container, it maintains the quality stability of the welding wires.

Step 2: Customized Carton Packaging – Balancing Protection and Brand Image

After vacuum packaging, we move to the second step: individual carton sealing.

Each vacuum-sealed spool of welding wire is placed in its own exclusive small carton – not a “one-size-fits-all standard box”, but a customized package tailored to the client’s needs. The carton surface can be printed with the client’s brand logo, product model, and even usage precautions. For clients, this is more than just an extra layer of protection; it ensures their products maintain a consistent brand image “from factory to client warehouse”, showcasing professionalism in the details.

Step 3: “Triple Protection” for Palletizing & Reinforcement – Tackling Long-Distance Sea Freight Challenges

Most flux-cored welding wires are exported by sea. With transportation cycles ranging from a few weeks to over a month, stacking pressure and constant bumping inside containers during transportation pose significant challenges.. That’s why we’ve implemented “triple protection” for the final “palletizing and reinforcement” step:

- Neat Palletizing: First, we place the cartoned welding wires on pallets according to the size requirements of the client’s warehouse. This ensures even weight distribution, preventing deformation of the bottom layer due to excessive local stacking – so the goods can fit perfectly into the client’s warehouse shelves upon arrival.

- Stretch Film Sealing: We use a machine to wrap the entire pallet from bottom to top with high-toughness stretch film. This not only prevents dust but also further enhances overall stability, stopping cartons from shifting during transportation.

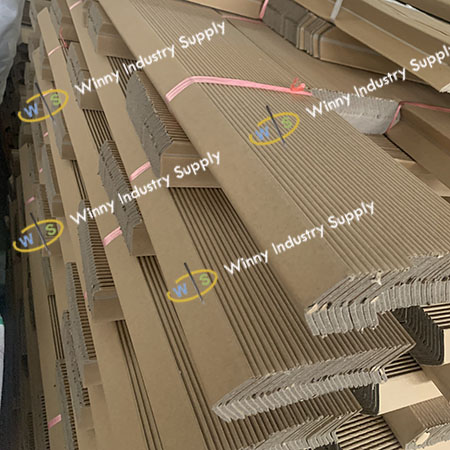

- Dual Reinforcement with Paper Corners & Straps: For all sea freight orders, we install rigid paper corners around the pallets to protect vulnerable edge areas from bumps. Finally, we use high-strength straps to secure the entire pallet in a “well-shaped” pattern. Even if the container encounters severe bumps at sea, the pallet will not shake or fall apart.

Visible Peace of Mind: Every Step Leaves a “Trace” – Full Traceability Guaranteed

To us, “packaging standards” are not just processes – they are a “trust guarantee” for clients. Therefore, for all export welding wire orders, we keep photos and videos of the packaging and container loading process. In the unlikely event of an accident during transportation, these materials allow us to quickly trace the problem and help clients resolve it promptly. No more “guessing about packaging through imagination” or “worrying about being kept in the dark” – this is our commitment to every client.

After all, in export trade, success depends not only on product quality but also on the responsibility to “deliver products safely to clients”. If you have needs for flux-cored welding wires or other industrial consumables, our packaging standards are always here to safeguard your shipments.